Underwater Fiber-Optic Communication Line Laying

Underwater fiber-optic cable laying projects include:

- Design of the communication line and communication node equipment

- Laying of communication line underwater part

- Burial of communication line in the soil at coastal and shore sections

- Equipment installation and setup at communication nodes

- Carrying out commissioning works

PROJECT TEAM

For the implementation of the underwater fiber-optic cables, Ensis Technologies formed a cooperation of Russian companies and 170 specialists (engineers, designers, technologists), having unique competence and experience.

APPROVALS AND PERMITS

A permit is required from Rosprirodnadzor for the construction of underwater communication lines. The project team has a successful experience in obtaining all permits, including obtaining water use and compensation for environmental damage.

THE VESSEL

To carry out the work, Ensis Technologies uses the Rubin vessel with a payload capacity of 1,100 tons, equipped by the company with all the necessary equipment for laying fiber-optic cables. Including paired cable baskets (tenks), cable bridges (roller conveyors), a laboratory for coupling assembly and underwater amplifier tuning, an unwinding machine for cable drums 3.6 m in diameter, weighing 40 tons, paired cable pushers (cable line machines) with electronic control with a pulling force of over 10 tons.

All specialized tooling developed by the specialists of Ensis Technologies are made in Russia.

SUBMARINE CABLE INSTALLATION

The Ensis Technologies specialists, cable party employees, and the vessel's crew worked out coordinated operations and technologies for laying the optical cable in the paired cable basket, passing the cable from the tangents through roller conveyors, cable line machines, and lowering the cable through the slipway into the sea.

On the coastal sections the fiber optic cable is laid deep into the ground. Fleet is used for offshore construction, consisting of pontoon with navigation equipment, crane for moving raid equipment, tugboats, rescue and measurement boat with diving station, excavator with trencher and plow. The works are performed under the control and with the participation of divers.

Onshore sites the work is done on laying cable lines to communication nodes by cable suspension, in sewers or in the ground; grounding loop installation is done, installation of the necessary engineering systems and equipment for communication nodes is carried out.

The Ensis Technology specialists developed and tested algorithms for controlling the optical and electrical parameters of the installed underwater fiber-optic communication line under real conditions.

MATERIALS AND EQUIPMENT SUPPLY

As part of the project, Ensis Technologies provides delivery of all cable products, equipment and materials. An important stage in the preparation of the vessel is working out the logistics of oversized cargo, including the transportation of 40-ton cable drums with a diameter of 3.6 meters, as well as other oversized equipment to equip the vessel.

THE FINAL STAGE OF THE LAYING PROJECT

At the final stage, commissioning works, adjustment of the communication node equipment, acceptance tests are carried out.

All works on construction of underwater fiber-optic communication lines are performed in accordance with the terms of reference agreed with the customer and under control of the customer's internal technical supervision.

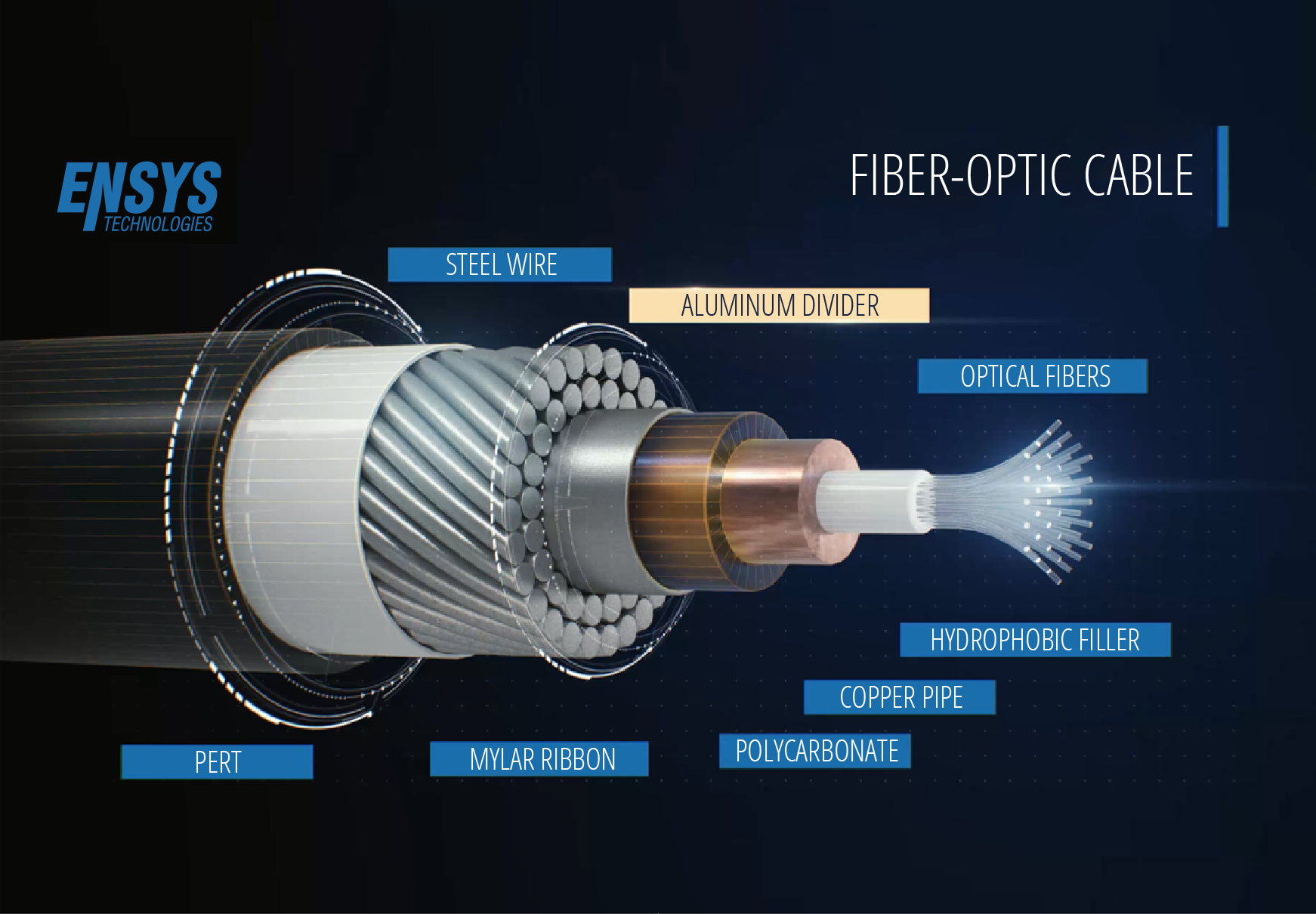

TECHNICAL DATA AND COMPONENTS

The maximum capacity of submarine fiber-optic communication lines without structural changes in the equipment of the submarine linear path is up to 10 Tbit/s.

For laying the underwater fiber-optic communication lines the optical cable with or without conductive core is used, depending on the conditions of the project.

A set of Russian-made equipment is used as the transmission system for construction of underwater fiber-optic communication lines, including:

- Spectral multiplexing equipment

- Underwater line cable equipment

- Synchronous digital hierarchy transmission equipment.

Software-controlled multifunctional primary multiplexers are used as subscriber access equipment.

On the deep section of the line provides for the use of:

- Protective polyurethane covers in the complex sections of the line

- Cable couplings: underwater couplings, underwater tap couplings, near-shore couplings

- Underwater Line Amplifiers as part of the complex.

The Underwater Line Amplifiers is designed to amplify DWDM optical signals at 1530-1565 nm wavelengths transmitted over optical fibers in two independent directions of the linear path between repeater sites of a submarine fiber-optic communication line (FOCL).

The Underwater Line Amplifiers are remotely controlled, supported by the process control and management system software.

The Underwater Line Amplifiers power supply is carried out by a remote power system (RPS), converting three-phase AC voltage, 220 V/380 V, frequency 50 Hz into a constant stabilized voltage of 27 V. The RPS consists of remote power equipment and remote power receivers.